3D printing has revolutionized manufacturing and creative industries, but its limitations remain a critical discussion point—especially the maximum size of objects a 3D printer can produce. This article delves into factors determining the build size of 3D printers, technological advances enabling large-scale printing, and current use cases across industries, helping readers understand the future potential of these innovative machines.

Introduction

3D printing, once a niche technology, is now reshaping how products are designed and manufactured. Among the key considerations for any user is the size limitation of the objects a printer can produce. From desktop models crafting intricate miniatures to industrial giants constructing entire houses, the build size of 3D printers varies significantly. But what defines these limits, and how big can 3D printers actually go? Let’s explore the technological, material, and application aspects shaping the answers to these questions.

Understanding Build Volume in 3D Printers

The build volume of a 3D printer refers to the maximum dimensions an object can have when printed. It’s defined by the printer’s axis range—commonly represented as width × depth × height. For instance, a consumer-grade 3D printer might have a build volume of 220 × 220 × 250 mm, suitable for hobbyists and small-scale projects.

Factors Influencing Build Volume

- Printer Design

- Cartesian vs. Delta Printers: Cartesian printers, with rectangular build volumes, are commonly used for precision tasks, while delta printers offer a cylindrical build area, often accommodating taller objects.

- Gantry Systems: Industrial printers use gantry systems or robotic arms, which support larger, more complex build areas.

- Material and Printing Technique

- FDM (Fused Deposition Modeling) is widely used but often limited by nozzle control over larger areas.

- SLA (Stereolithography) and SLS (Selective Laser Sintering) can achieve higher precision but have material and size constraints based on laser movement.

- Stability and Precision

Larger printers require advanced stabilization and precision mechanisms to prevent layer misalignment or distortion over extended build times.

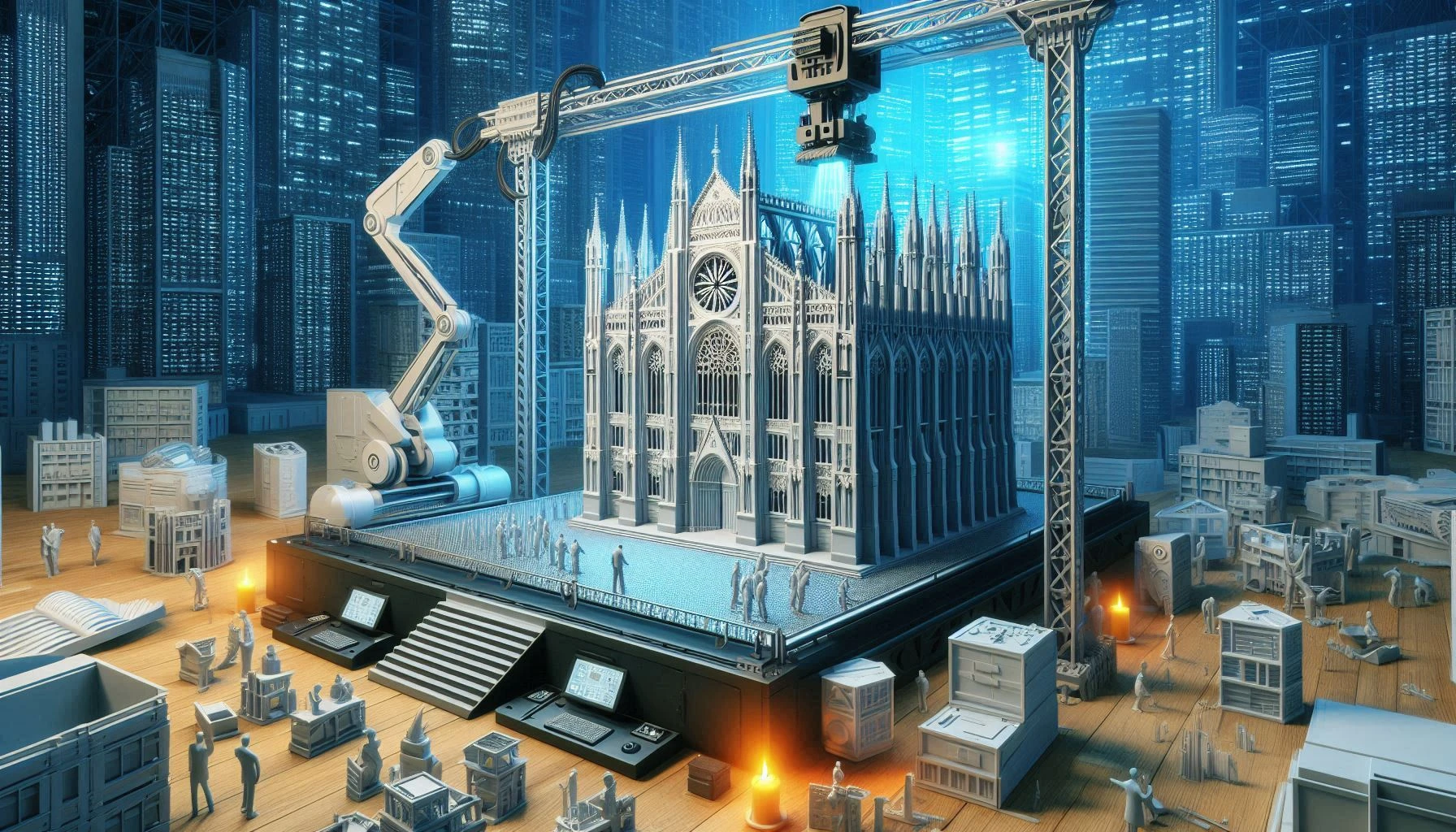

Breaking Barriers: Large-Scale 3D Printing

While desktop 3D printers dominate consumer markets, industrial-grade machines are pushing boundaries. Large-scale 3D printing technologies like Big Area Additive Manufacturing (BAAM) and Concrete 3D Printing have redefined what’s possible.

Examples of Large-Scale Printers

- Boeing’s BAAM Systems: Capable of printing aerospace components as large as 20 × 8 × 6 feet.

- ICON’s Vulcan Printers: These printers construct full-sized houses using concrete layers, with build volumes stretching several meters in each dimension.

- Mammoth SLA Printers: Designed for automotive and architectural models, they offer precise outputs over areas exceeding two meters in width.

Applications

- Construction: Large-scale printers are used to build homes, bridges, and even disaster shelters. For example, in 2021, entire neighborhoods of 3D-printed homes were developed for affordable housing initiatives.

- Aerospace and Automotive: Manufacturers create lightweight yet robust vehicle and aircraft components, reducing production costs and time.

- Art and Installations: Artists use large-scale printers to bring intricate, oversized sculptures to life.

Challenges and Limitations

Despite impressive advancements, several challenges remain in scaling up 3D printing.

- Material Constraints

Printing larger objects requires substantial material volumes, and some materials are not feasible for extended builds due to cost or durability limitations. - Printing Time

Large-scale projects can take days or weeks, increasing energy consumption and project costs. - Precision Trade-offs

The larger the build volume, the harder it becomes to maintain accuracy and avoid structural flaws. - Post-Processing Needs

Large objects often require additional steps, such as sanding, painting, or assembling smaller sections.

Innovations Expanding Build Size

The future of 3D printing promises solutions to current limitations.

- Modular Printers: Systems where parts are printed separately and assembled later are growing in popularity for projects exceeding single-build capacities.

- Advanced Materials: New composites, such as carbon fiber-reinforced polymers, enable lighter, more durable structures at larger scales.

- Automation and AI: AI-powered quality control ensures that precision is maintained across extensive builds.

Comparing Consumer and Industrial Printers

| Feature | Consumer Printers | Industrial Printers |

|---|---|---|

| Build Volume | 200–300 mm per axis | Up to 20 feet or more |

| Applications | Prototypes, small crafts, and tools | Construction, aerospace, and automotive |

| Cost | $200–$5,000 | $50,000–$1 million+ |

| Precision | High for small objects | Variable, depending on scale |

Conclusion

3D printers, from compact models to industrial giants, offer diverse capabilities when it comes to size. The largest printers today are capable of constructing buildings and massive vehicle components, but these advances come with their own set of challenges. As technology evolves, the possibilities for large-scale 3D printing are set to grow even further, opening doors to innovation in manufacturing, construction, and beyond.

Looking ahead, the future seems promising for both hobbyists and industries as engineers refine methods to balance size, precision, and efficiency. The question isn’t just how big 3D printers can print—but how they will reshape the world we build.

Leave a Reply